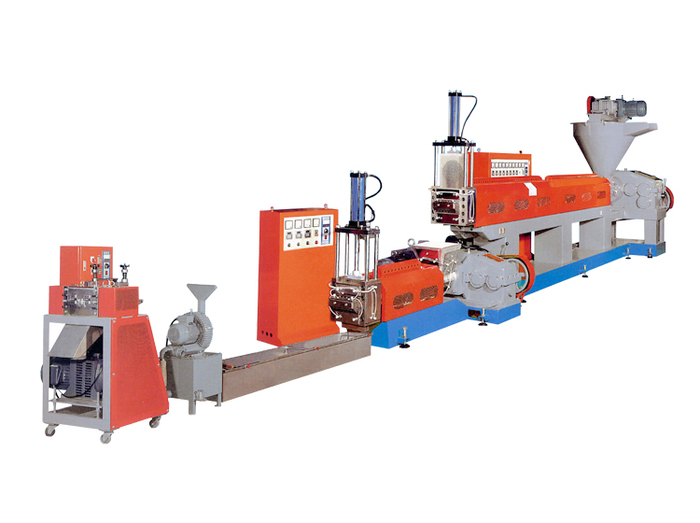

Plastic Pelleting Reproduction Machine (Two-Stage Type)

Plastic Pelleting Reproduction Machine (Two-Stage Type)

PPR-2 Series

The main difference between our PPR and PPR 2 (Plastic Pelleting Reproduction) is the method of processing the materials.

In PPR machines, this method filters waste and impurities in only one step. In PPR-2, there is a second step.

The second step is to re-filter the replicated material and filter more impurities through the process. This method, together with a refining step, makes the granular resin better, purer and cleaner.

| Model | PPR-2 Series | |||

|---|---|---|---|---|

| Description | unit | PPR-75-2 | PPR-100-2 | PPR-120-2 |

| Extrusion Output | kg/hr | 75- 125 | 120- 220 | 180- 330 |

| First Extruder Machine | ||||

| Screw Dia | m/m | 75 | 100 | 120 |

| Screw | l/d | 32/1 | 32/1 | 32/1 |

| Driving Motor | hp | 30 | 50 | 75 |

| Auto-thermo Controller | zones | 4 | 6 | 7 |

| Heater Capacity | kw | 25 | 35 | 52 |

| Speed Take-Up | 2 | 2 | 2 | |

| Forced Feeding Motor | hp v.s. | 3 | 3 | 5 |

| Hydraulic Screen Changer Motor | hp | 2 | 3 | 3 |

| Second Extruder Machine | ||||

| Screw Dia | m/m | 75 | 100 | 120 |

| L/D | 10/1 | 10/1 | 10/1 | |

| Driving Motor | hp v.s. | 10 | 15 | 25 |

| Auto-Thermo Controller | zones | 2 | 3 | 3 |

| Heater Capacity | kw | 7 | 12 | 15 |

| Water Cooling Tank | unit | 1 | 1 | 1 |

| Water Wing Mill | hp | 1 | 2 | 3 |

| Cutting Grain Machine | ||||

| Driving Motor | hp v.s. | 2 | 3 | 5 |

| Machine Weight | kgs | 2200 | 3200 | 4500 |

| Packing Size (L x W x H) | m | 3.5 x 1.7 x 1.3 | 4.3 x 2 x 1.5 | 5 x 2.2 x 1.5 |

分享